Blue Star Plus Decking

Machine Coated | Ready to Install

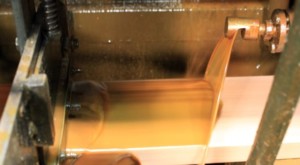

Each piece of Blue Star Plus decking is uniformly coated, brushed and buffed on our custom-designed finishing line. Every piece is hand wiped, then carefully dried in a dust-free environment.

A Blue Star deck is a good investment. Get the most value from your investment by using Blue Star Plus.

The following recommendations and suggestions are intended to provide you information that we have gathered during many years of building with Blue Star and other wood products. Our goal is to be realistic and forthright with our comments. We ask that you be realistic with your expectations. Remember, wood is a natural substance that reacts to weather and sunlight.

Oil-based deck finishes penetrate wood fibre to form a water-repellent coating. They do not “seal” wood against the intrusion of moisture, as many people believe. These finishes slow the absorption and expulsion of moisture. They help minimize surface checking (small, hairline cracks) and movement or distortion that can occur when wet lumber dries rapidly. They help your deck look, wear and perform better over its lifetime.

Deck finishes are not one-time, permanent coatings. All oil-based deck finishes will dissipate over time. Performance and appearance longevity for coated decking will depend on a number of factors. The quality of the timber and the brand of finish used are critically important. The direction a deck faces, the local climate, and the characteristics of any particular building site all play a role in determining the performance of the deck boards and the coating. Proper coating application produces the best, longest lasting results. Machine coating, when done correctly, will outperform hand coating.

All wood decks — even those that are intended to weather naturally — should be treated with an initial coating of penetrating oil finish. All boards should be coated on all surfaces, to uniformly retard the absorption and expulsion of moisture. Blue Star Plus provides you the all-important base coat of finish you need to achieve maximum performance and the best long-term appearance from our products.

UV PLUS for Hardwoods is a one-step translucent penetrating oil finish, specially formulated to enhance the natural characteristics of fine wood. It is the #1 choice in the Northeast for coating hardwood decks. With its superior penetrating agents, industry-leading UV protection, and premium fungicides, Messmer’s formulations offer the performance and ease of traditional oil-based finishes.

UV PLUS meets all federal and state/local environmental regulations for Volatile Organic Compounds (VOC).

For more information about UV PLUS for Hardwoods, and all other Messmer’s wood care products, visit www.messmers.com

For more information about finishing, maintenance, cleaning and refinishing, click the link below.

Touch-up finishing:

You may need to touch up some areas of your deck after it is first installed. Lightly sand the area(s) to be touched up, only if necessary. If sanding is not necessary, clean the specific areas with a solution of 3 parts water, 1 part household bleach and a squirt of liquid dish soap. Use a medium-firm brush or push broom to brush/scrub the surface, as needed. Rinse thoroughly with water (using a hose and nozzle) and allow the area to dry completely. (Never apply a coating of finish to wet boards.) Once the boards are dry, apply a light coating of Messmer’s UV PLUS for Hardwoods (Natural color) by brush, roller, or paint pad. (Do not over apply the finish.) Wipe any excess finish with a clean cloth. Allow the area to dry.

Regular maintenance:

After installing Blue Star Plus, you may wish to let your deck age naturally to a smooth, silver color. If this is your choice, you need not reapply additional coatings. Please note that a second coating will help your deck boards age better, and give you a better looking deck in the years ahead. Please remember that wood is wood! It will fade under sunlight, even if treated with a deck finish. Color can be restored or refreshed with maintenance. Over time, wood will fade to a silver color if left untreated. When weathering to its natural silver color, it may not weather uniformly all at once. You might need to give it time to achieve uniformity. If you choose to maintain a finished look, you will need to treat the deck with additional applications of finish, according to need. No matter which of these you choose, we recommend that you perform regular cleaning and maintenance on your deck, if you wish to achieve maximum performance and appearance.

Important facts about maintenance, deck cleaning, and refinishing:

- Your best bet for a long lasting, good looking deck is to keep your deck clean. Regular sweeping and rinsing with a hose and nozzle will help keep surface dirt and debris from building up. An occasional light scrubbing with a medium-stiff brush does wonders. If your deck tends to build up dirt, grime or mildew, clean it occasionally with a mild cleaning solution. If you keep your deck clean and well maintained, the job of refinishing will be much easier, and produce better results.

- There are dozens — if not hundreds — of commercial products available for cleaning, brightening and stripping decks. For every one of these products, there are an infinite number of opinions about how to use them. If you are concerned or confused about which products to use, or how to use them, consult your local lumber dealer. Or, send us your questions by email.

- Cleaners, brighteners, and strippers have different purposes. Which of these is appropriate for any specific job will depend on the condition of the deck. If you are unsure about which product you require, consult with your lumber dealer, or with a qualified deck builder/contractor. Or, email us your pictures and questions.

- One common instruction for using cleaners and brighteners is to keep the wood wet with the cleaning solution for 10-20 minutes. This is a good tip. During this time you need to scrub the wood with a medium to stiff brush or push broom. This scrubbing will help dislodge dirt, debris, or worn finish from prior coatings.

- Sanding a deck to bring it back to original condition is always an option. This is a more intensive process than cleaning or stripping. You can avoid the need to sand a deck if you perform regular cleaning and refinishing.

- Never use a pressure washer as a “cleaning” tool on your deck. A pressure washer is a valuable tool in the deck cleaning process, but it should be used for rinsing – not for cleaning your deck.

- A pressure washer can be your friend…or, it can be your enemy! When used at a high-pressure setting and held too close to wood, a pressure washer can rupture surface fibres and create a fuzzy or hairy surface. It can also etch the surface of boards when used improperly.If you choose to use a pressure washer in any deck cleaning process, begin with a low pressure setting and a nozzle/fan setting of 40 to 60 degrees (about enough to wash two to three 6″ deck boards, or three to four 4″ deck boards, when held 1 foot from the surface). Use only enough pressure to rinse your deck thoroughly. Do not exceed 500 psi. Wash/rinse the boards with a sweeping motion, keeping the tip of the nozzle about one foot from the boards (no closer). Test a small area to determine if cleaning is adequate and if no damage to the wood fibre has occurred. If this setting works, keep going. If cleaning is not adequate, use a stronger cleaning solution. Remember, it is best to let your cleaning solution and brush do as much of the work as possible. A pressure washer is for rinsing!

Is my deck ready for another coat of finish?

- Most manufacturers of decking finishes claim that their products will provide protection for 12-24 months. For every deck, there are a number of variables that will determine the performance longevity and the look of a finished deck. These manufacturers are careful not to overstate the performance of their products. At the same time, they need to state performance indicators that make their products sound great.

- In our experience, the “12-24 month rule” is often misunderstood. While the coating may continue to provide a level of protection during this time, it is unlikely that the “color” will hold for a full year.

- If you want to retain the “finished” color of your deck, expect to re-coat it often, according to need.

- Most- if not all-manufacturers of deck finishes will tell you that you need to wait for the previous coating to completely dissipate before refinishing. They know, from experience, that over-coating can lead to messy and unattractive buildup. Also, certain “oily” finishes may have difficulty adhering to existing layers of finish.

- There are many schools of thought on this subject. The traditional “acid test” to determine if your deck is ready for another coating is: Does the old coating still repel water? To determine this, test your deck boards by pouring water on a small area. If the boards repel water, the finish is still working. If the boards absorb water, you are ready to refinish.

- If you wait for the original coating to totally dissipate, you may experience color fading in the lumber itself. This is to be expected. All wood, and all wood finishes fade under sunlight.

Cleaning your deck before refinishing:

- When the time comes to prepare your deck for a maintenance coat of finish, the first — and most important — step is to give the deck a good, thorough cleaning. It is crucial that you remove all embedded dirt, and all remnants (particles) of old finish before you re-apply a coating of oil to your deck boards.

- We recommend that any deck cleaning project begin with a mild cleaning solution, to check results. You can always ramp up the intensity of the cleaning solution if you aren’t achieving a thorough cleaning.

- We have experienced excellent results using a cleaning solution of: 3 parts water, 1 part household bleach, and a healthy squirt of liquid dish soap. Using this solution, follow these steps:

- Sweep or blow your deck clean of all loose debris.

- Rinse the deck clean using a garden hose and nozzle.

- While the deck is still wet, apply a liberal amount of the cleaning solution to the deck boards (the best application is achieved using a garden sprayer).

- Let the solution sit on the wood for 10-20 minutes. During this time, scrub the surface with medium-stiff brush or push broom. Keep the boards wet during this process.

- Rinse the deck thoroughly with a hose and nozzle, or gently rinse using a power washer. If you use a power washer, use a low pressure setting. Do not exceed 500 psi. Maintain a nozzle/fan setting of 40 to 60 degrees. Keep the nozzle about one foot from the surface of the wood, and wash with a sweeping motion. Rinse thoroughly.

- Allow the deck to dry for a minimum of 48 hours before applying the next coat of finish. (Be sure the deck is thoroughly dry before refinishing.)

- If the cleaning solution recommended above is not powerful enough to clean your deck, try the following solution: 2 ounces of 100% powdered tri-sodium phosphate (TSP) dissolved in 3 quarts of water and 1 quart of liquid bleach.

- Using this more powerful solution, follow the same cleaning procedures outlined above.

- Most commercial deck cleaners contain TSP. This powerful detergent helps deep clean wood and dislodge dirt and broken down particles of old coatings. It is a time-tested product and can be used in combination with other cleaning substances. Used alone in a strong solution, it can bleach the color of your decking. (TSP is available for purchase at most lumber yards and hardware stores.)

- If these solutions and procedures will not clean your deck adequately, you may need to use a deck brightener or a deck stripper. Consult your local lumberyard to find products that are available in your area.

- When using any commercial products to clean or prepare your deck, always pay attention to the manufacturer’s instructions.

- Once your deck is clean, allow the deck boards to dry completely. This is important! Finish does not adhere well to wet surfaces. You are now ready to apply a new coat of finish.

Refinishing your deck:

- As soon as your deck boards are dry, you should apply the next coat of finish.

- We recommend you test finish a small area to become familiar with the finish, to be sure the finish adheres properly, and to be certain that you are satisfied with your choice of colors. When you are ready to go:

- Sweep or blow all dirt, dust, and debris from the deck surface. The cleaner your surface, the better your coat of finish will perform.

- When applying your next coat of finish, follow the rule: LESS is MORE. Do not over apply the coating. A thin, even layer of finish is all that is required. A heavy coating may have difficulty bonding to the wood, and is a waste of material. (Depending on the condition of your deck, one gallon of Messmer’s UV PLUS can cover as much as 350 sq. ft., using manual application.)

- For a good coating and an efficient job, apply the finish with a roller or a paint pad, attached to a long handle. Spread evenly, using some pressure, and wipe any excess away with a clean cloth. (Be sure to follow customary care and disposal procedures for rags that contain any trace of finish.)

- Allow the finish to dry. Always give the boards a little extra drying time.

Messmer’s Finishes

The #1 choice in hardwood decking by East Coast builders for more than 25 years is now available factory coated with Messmer’s UV PLUS for Hardwoods.

Sharing is caring!